Understanding LCD Controller Board Technology Evolution

The display technology industry has witnessed remarkable advancements in recent years, with LCD controller boards playing a pivotal role in driving high-resolution displays. These sophisticated components serve as the bridge between raw display data and the visual output we see on screens. As display resolutions continue to push boundaries, the distinction between 8K and 4K LCD controller boards becomes increasingly significant for manufacturers, integrators, and end-users alike.

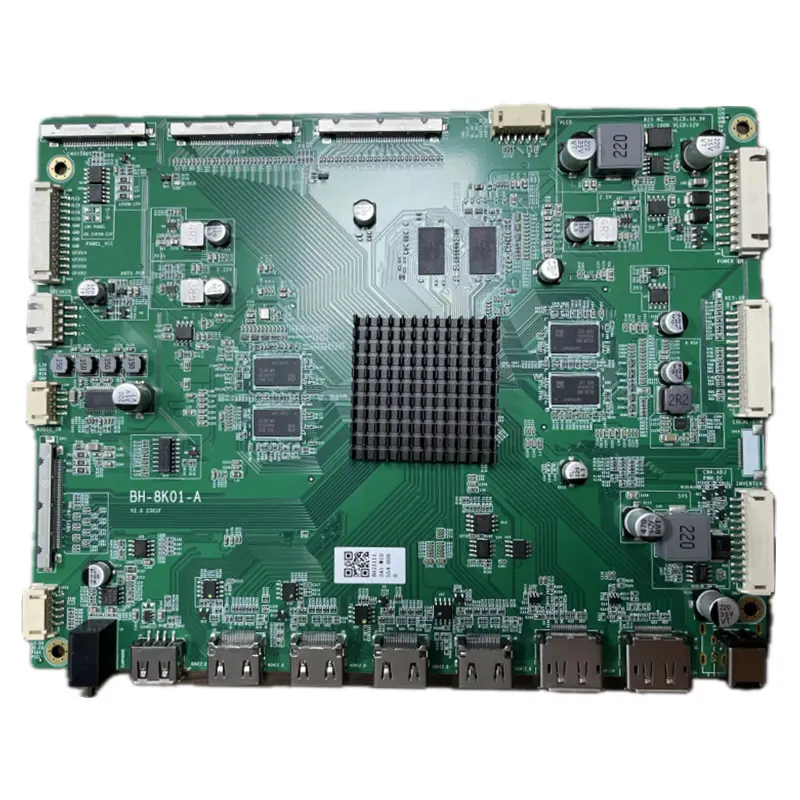

LCD controller boards represent the heart of modern display systems, processing complex signals and managing millions of pixels in real-time. The transition from 4K to 8K technology marks a significant leap in display capabilities, bringing both opportunities and challenges for various applications across industries.

Technical Architecture and Processing Capabilities

Processing Power and Memory Requirements

The fundamental difference between 8K and 4K LCD controller boards lies in their processing capabilities. 8K controller boards must handle approximately four times the pixel data compared to their 4K counterparts. This massive increase in data throughput requires significantly more powerful processors and larger memory buffers. While 4K LCD controller boards typically process around 8.3 million pixels, 8K boards manage an impressive 33.2 million pixels per frame.

Memory bandwidth and cache systems also differ substantially between these controllers. 8K LCD controller boards incorporate advanced memory management systems with higher bandwidth capabilities, often utilizing DDR4 or newer memory standards. The increased memory requirements directly impact the board's design complexity and component selection.

Signal Processing and Timing Control

Timing control represents another crucial aspect where 8K and 4K LCD controller boards diverge significantly. 8K controllers require more sophisticated timing mechanisms to maintain synchronization across the larger pixel array. The signal processing circuits must operate at higher frequencies while maintaining signal integrity and minimizing electromagnetic interference.

The complexity of scaling and image processing algorithms also increases substantially with 8K LCD controller boards. These boards implement advanced scaling engines capable of handling various input resolutions while maintaining image quality across the larger pixel matrix.

Interface and Connectivity Solutions

Data Transfer Protocols

The interface requirements for 8K and 4K LCD controller boards differ significantly in terms of bandwidth and protocol support. 8K controller boards typically utilize newer interface standards such as DisplayPort 1.4 or HDMI 2.1, which provide the necessary bandwidth for handling higher resolution content. These advanced interfaces support higher refresh rates and enhanced color depth, essential for professional applications.

4K controller boards, while still capable of handling substantial data throughput, can operate with earlier interface standards like DisplayPort 1.2 or HDMI 2.0. The selection of interface protocols impacts not only performance but also compatibility with source devices and overall system design considerations.

Physical Connectivity Options

The physical connectivity architecture of LCD controller boards varies between 8K and 4K models. 8K boards often incorporate multiple high-speed lanes and may require additional connectors to handle the increased data flow. This can result in more complex PCB layouts and stricter requirements for signal integrity management.

Power delivery systems also differ, with 8K LCD controller boards typically requiring more robust power management solutions to support their increased processing demands. The physical design must account for thermal management considerations due to higher power consumption.

Performance and Quality Considerations

Image Quality and Processing Features

The impact on image quality between 8K and 4K LCD controller boards extends beyond mere pixel count. 8K controllers often incorporate more advanced image processing capabilities, including superior scaling algorithms, enhanced color management, and more sophisticated motion handling. These features become crucial when displaying content across the vastly increased pixel array.

HDR processing capabilities also differ, with 8K LCD controller boards typically offering more advanced HDR processing pipelines. This includes support for wider color gamuts and higher dynamic range, essential for professional content creation and high-end display applications.

Response Time and Refresh Rates

The handling of refresh rates and response times presents unique challenges for both controller types. 8K LCD controller boards must process significantly more data while maintaining acceptable refresh rates. This often requires more sophisticated frame buffer management and potentially new approaches to reduce latency.

While 4K controllers can more easily achieve higher refresh rates due to lower pixel counts, 8K controllers must balance performance with practical limitations of current interface bandwidths and processing capabilities.

Implementation Considerations and Future Outlook

Cost and Manufacturing Implications

The manufacturing complexity and component requirements for 8K LCD controller boards result in higher production costs compared to 4K alternatives. The need for more advanced processors, larger memory configurations, and sophisticated PCB designs contributes to this cost difference. However, as technology advances and manufacturing processes improve, this gap is expected to narrow.

Implementation costs extend beyond the hardware itself, including considerations for thermal management, power supply requirements, and system integration complexity. Organizations must carefully weigh these factors against their specific application requirements and budget constraints.

Future Technology Trends

The evolution of LCD controller board technology continues to accelerate, with new developments promising to address current limitations. Emerging technologies such as artificial intelligence-assisted processing and advanced compression algorithms may help bridge the performance gap between 8K and 4K implementations.

Industry standardization efforts and the development of new interface protocols will likely shape the future of both 8K and 4K LCD controller boards. These advancements will influence both the technical capabilities and practical applications of these technologies.

Frequently Asked Questions

What are the power consumption differences between 8K and 4K LCD controller boards?

8K LCD controller boards typically consume 30-50% more power than their 4K counterparts due to increased processing requirements and higher memory bandwidth needs. This increased power consumption necessitates more robust cooling solutions and power supply specifications.

Can 4K LCD controller boards be upgraded to support 8K resolution?

Generally, 4K LCD controller boards cannot be upgraded to support 8K resolution as the hardware architecture, processing capabilities, and interface requirements are fundamentally different. A complete board replacement is necessary for 8K support.

What are the primary applications driving 8K LCD controller board adoption?

The main applications driving 8K LCD controller board adoption include professional video production, medical imaging, high-end digital signage, and advanced scientific visualization. These sectors benefit from the increased detail and precision offered by 8K resolution.